Things about Inventory Management

Wiki Article

The Greatest Guide To Inventory Management

Table of ContentsSome Known Facts About Inventory Management.Excitement About Inventory ManagementInventory Management - An OverviewThe smart Trick of Inventory Management That Nobody is Discussing

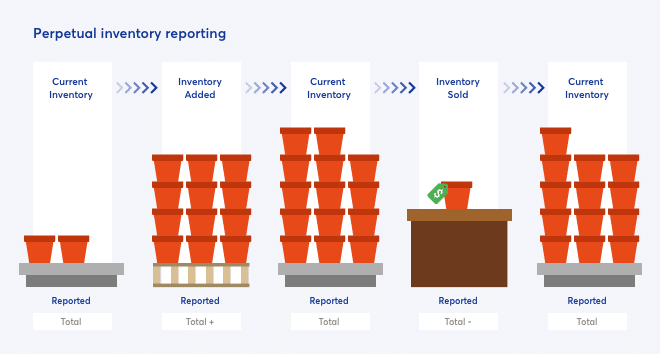

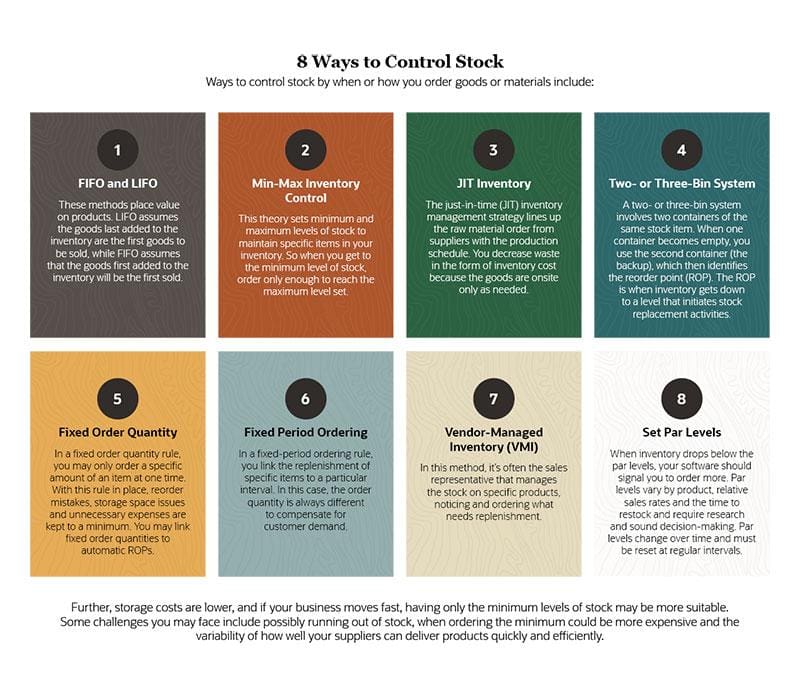

There are two major approaches of tracking inventory: periodic as well as perpetual. The main difference in between these is just how frequently information is updated. Despite just how commonly you track stock, you may intend to utilize one of the complying with supply management techniques: ABC Analysis, ABC (Always Better Control) Evaluation is supply administration that separates various products into three categories based on pricing and also is separated right into teams A, B, or C.EOQ Design, Economic Order Quantity is a strategy utilized for planning and buying an order amount. It entails making a choice pertaining to the quantity of supply that ought to be positioned in stock at any type of offered time.

FSN Method, This technique of stock control refers to the procedure of tracking all the things of supply that are not made use of often or are not required regularly. They are then classified right into 3 different classifications: fast-moving supply, slow-moving inventory, and also non-moving inventory. JIT Method, Just In Time inventory control is a process made use of by makers to control their inventory degrees.

The Buzz on Inventory Management

VED Analysis, VED is a strategy made use of by organizations to control their inventory. It primarily pertains to the management of important and also preferable spare components. The high degree of inventory that is needed for production generally justifies the low supply for those components. Among the most crucial factors that a business should consider is the accuracy of the details provided in its inventory databases.Wrike is a project monitoring solution that can assist you do precisely that. With Wrike's product monitoring devices, you can manage every one of your product team's activities in one area and get one of the most out of every project. Wrike's product launch automation aids accelerate item launches with a structured approach.

Things about Inventory Management

Inventory administration describes the procedure of buying, keeping, using, click here for more info and selling a firm's supply. This consists of the monitoring of raw products, components, as well as ended up products, along with warehousing and handling of such items. There are different kinds of supply administration, each with its pros and also disadvantages, depending on a firm's needs.Supply monitoring attempts to successfully improve stocks to avoid both excess and scarcities. 4 significant stock monitoring techniques consist of just-in-time administration (JIT), products requirement preparation (MRP), financial order quantity (EOQ), and days sales of stock (DSI). There are pros as well as disadvantages to each of the approaches, examined below. A firm's stock is among its most useful properties.

A scarcity of inventory when and where it's required can be very detrimental (Inventory Management). At the same time, supply can be thought of as an obligation (if not in an accountancy sense). A big stock carries the risk of perishing, burglary, damage, or changes in demand. Supply should be insured, and also if it is not offered in time it might have to be gotten rid of at clearance pricesor just ruined.

Tiny businesses will certainly typically maintain track of supply by hand and figure out the reorder factors and also amounts making use of spreadsheet (Excel) formulas.

The Ultimate Guide To Inventory Management

Appropriate stock management approaches vary relying on the market. An oil depot is able to keep large amounts of stock for extended time click here for more info periods, enabling it to await demand to select up. While saving oil is expensive and also riskya fire in the U.K. in 2005 led to countless pounds in damage as well as finesthere is no danger that the inventory will spoil or go out of her response design.For firms with complicated supply chains and also producing procedures, stabilizing the risks of inventory gluts and scarcities is particularly tough. To accomplish these balances, companies have actually developed a number of techniques for supply management, including just-in-time (JIT) as well as materials need preparation (MRP). Some companies, such as monetary solutions firms, do not have physical stock therefore has to rely upon solution process administration.

Inventory has to be literally counted or measured prior to it can be placed on a balance sheet. Finished products are finished items conveniently available for sale to a company's consumers. Depending on the kind of company or product being evaluated, a business will utilize numerous supply monitoring methods.

Report this wiki page